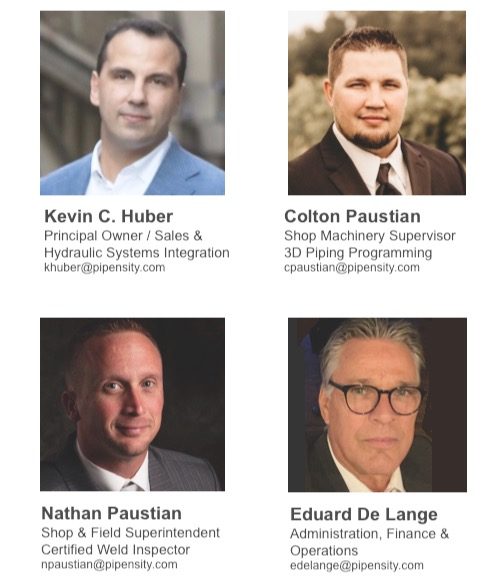

Team Pipensity

.

Meet The Team!

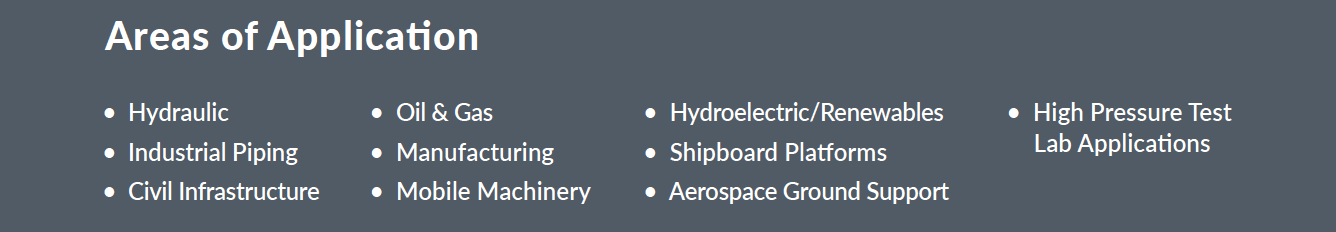

Pipensity serves clients in a wide range of industries, including hydraulic systems, pneumatic systems, and more. We can offer custom design solutions using experienced hydraulic piping engineers. We also have a deep understanding of industrial, mobile, and shipboard hydraulic systems. With over a combined 100 plus years experience in hydraulic systems-, piping engineering and fabrication, Team Pipensity is up to the task!

Planning

You don't just get pipes from us. We listen to you, think with you and use our specialized knowledge to explore practical and economical options. With a holistic view, we support you competently and comprehensively.

Consultation

Our large machine park with readily available tools and an extensive stock of semi-finished products ensures particularly fast production and cost advantages. Fully automatic CNC bending machines, systems for all forming processes and clean, non-cutting cutting processes are available for this. We offer you bending data acquisition, measurement reports, series and prototype acquisition as well as 3D modelling, and connections including welded, flanges, swage lock, pyplok, compression, flared or order plain end.

Why Work with Us?

Making pipes better, means planning ahead. Pipensity is future focused, and on your side as a dialogue partner at every level. Because we offer you expert knowledge in all relevant application areas. This is our consistent claim, so that we can use our specialist knowledge perfectly and you can be sure of the best result. We want to clearly record and successfully implement the wishes of our customers - in planning, quality, economy and timing. This ensures our and your success!

The special proximity to our customers is an important strategic tool for us. Consistency and reliability in contacts with our supplier partners guarantee a high degree of flexibility. And finally, the satisfaction of our employees is the basis for the satisfaction of our customers. Pleasure at work opens up space for good ideas and encourages planning imagination. This is the minimum requirement for us. Above all, our customers appreciate the systematic way to get there and the flexible, economical, and high-quality implementation!

_________________________________________________________________________________________

Client Feedback

"As a major hydraulic systems provider to critical infrastructure projects, Arch Hydro, Inc. has relied on Pipensity to provide and supply custom hydraulic pipe spools. Arch Hydro has often called upon Pipensity’s excellent team of experts to provide value engineered piping on such projects as the Lagrange Lock and Dam in Versailles, Illinois, Red Rock Dam in Des Moines, Iowa, as well as McNary Hydroelectric Dam Intake Gates, Umatilla, Oregon, and Poe Lock arrestor hydraulic piping systems rehab in Sault Sainte Marie, Michigan. Pipensity is always ready and able to execute our clients necessary hydraulic pipe forming and supply. Pipensity uses AutoDesk Inventor 3D modeling software along with their state of the art pipe forming machinery. Pipensity fully models each piping system to specs and maximizes the prefabrication process to minimize installation time. Thanks to Pipensity hydraulic pipe spool forming capabilities, design, manufacture, supply, and testing operations were successfully completed and turned over to our clients for timely delivery and installation."

ARCH HYDRO, Inc.

© 2023 All rights reserved. Pipensity, LLC